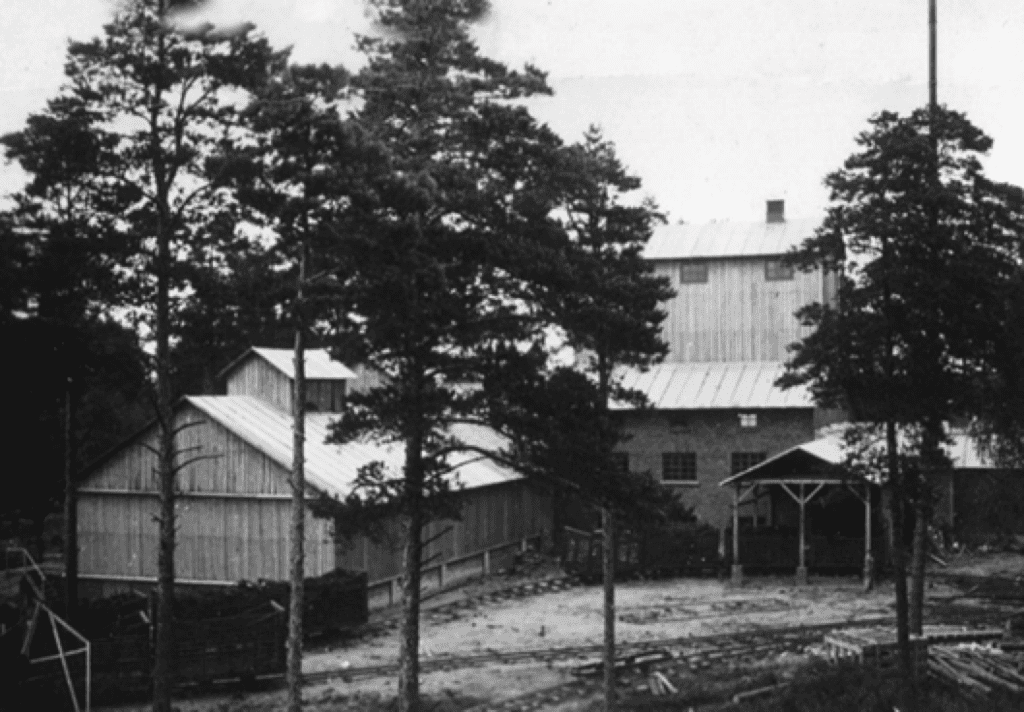

The board of the Lithuanian Pieno centras (Milk Centre) built a peat litter factory in Šepeta: three warehouses for storing raw material, a two-storey brick office building, and a residential house with a garage, as well as 40 km of narrow-gauge railway.

1936

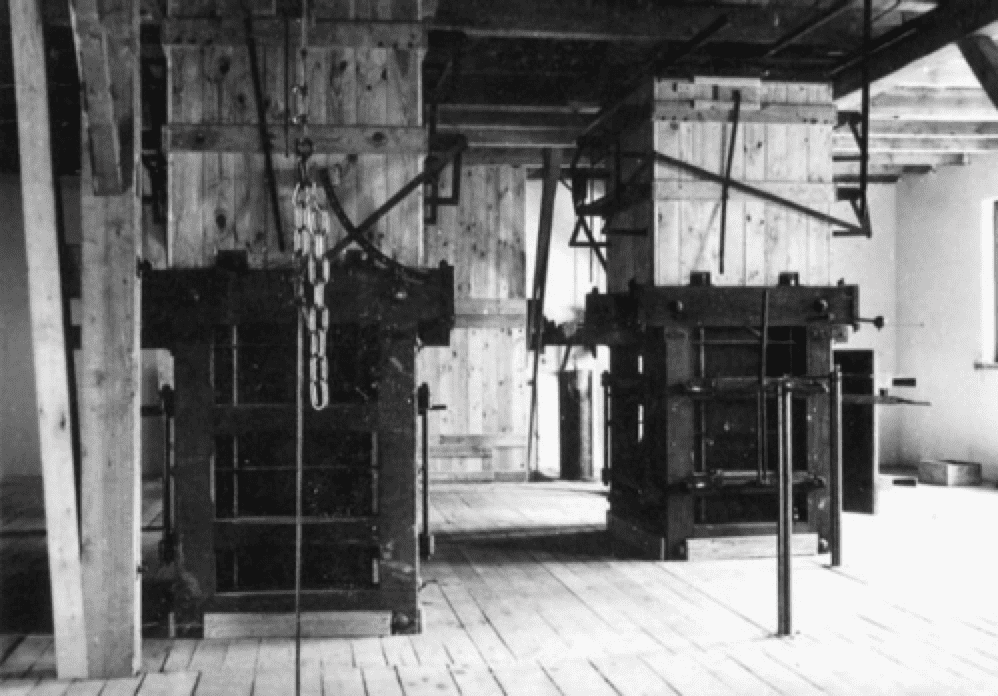

The new peat litter factory in Šepeta was opened and the first peat litter bales were produced using German peat-pressing equipment.

August 1940

A blacksmith’s shop was added and a second German peat litter press made by A. Beck was installed.

1942

The Šepeta peat litter factory was taken over by Lithuania’s Ministry of the Meat and Dairy Industry and was renamed the Šepeta Wood Processing Workshop, which employed 13 people at the time. Between 1948 and 1951, it produced materials for transporting eggs, sausage tins, and butter barrels, as well as firewood for wood-burning stoves.

1948

The Šepeta Wood Processing Workshop opened the Šepeta Wooden Tare Board Factory, which produced a variety of wooden packaging products.

2 October 1952

The Šepeta Wooden Tare Board Factory was taken over by the Republic Material-Technical Supply Office. The factory was transferred to the Peat Industry Trust (Torfotrest) and was renamed the Šepeta Peat Litter Factory, which at that time employed 65 workers.

July 1953

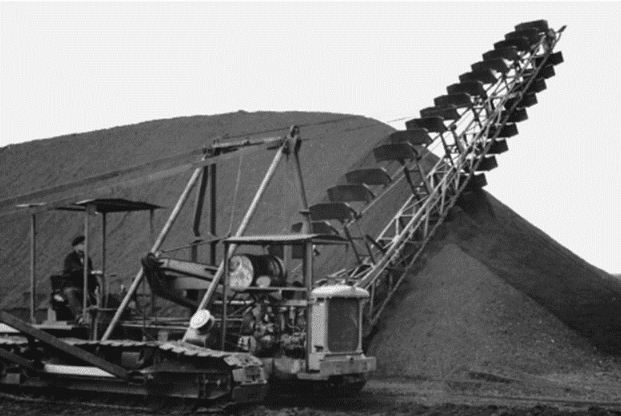

During the busy season, 500-650 people worked at the plant. There were 100-150 peat diggers, and around 200 women worked in four peat-drying teams.

1954–1963

Extraction of peat for fuel was started in the peatlands of Laičiai, Naivių and Juodymas in Kupiškis District.

1958

A new pressing workshop was opened at the plant. Two 8-unit houses and outbuildings were built in Šepeta.

1960

The company’s administration moved into the newly-built office building. The first floor housed a shop, canteen, communications department, and medical point, and the second floor housed the factory administration, library and cultural centre.

1962

A mechanical workshop was built.

1964

A new insulation panel workshop was opened, producing around 10,000 m3 of panels annually.

1969

The Panevėžys Peatland Office was merged with the Šepeta Peat Litter Factory, and was renamed the Kupiškis Peat Company, with its main office in Šepeta.

1 January 1974

Two compression-bagging lines made by the Canadian company Verville were installed at the Šepeta peatland. Peat was pressed into 300/250/150-litre polyethylene bags.

1984

Export of peat was begun to Germany, Italy, Greece, Israel and France.

1985

With permission from the Republic Production Association Lietuvos durpės (Lithuanian Peat), the Aliai peatland of the Margiai Peat Company was transferred to the Kupiškis Peat Company on 1 November 1990. On 19 November, the name of the Kupiškis Peat Company was changed to Kupiškis State Peat Company.

29 October 1990

The Kupiškis State Peat Company was privatised and became a joint-stock company.

1993

The Kupiškis State Peat Company was re-registered as the joint stock company Durpeta. At that time, the company had 123 full-time employees.

28 April 1994

It was begun to package peat in bulk bags (FIBC) using Swedish packaging equipment at the Aliai peatland.

1995

A new substrate production and packaging line was installed, in cooperation with an Italian firm.

1996

Production of bulk bags (FIBC) was begun in Šepeta.

1997

The first bag of peat substrate for professional use was produced.

15 February 1997

The first wheeled tractors and a wheeled loader were purchased, to speed up production in the fields.

1998

A new substrate production line began to operate in a new building, marking another milestone for the company, with the participation of a Czech company. The substrates were exported to Poland, Czechia, Hungary and Slovakia.

2000

With the approval of the shareholders, a controlling stake of 60.78% in UAB Kuršėnų tyras was acquired.

2000

UAB Durpeta was reorganised after merging with UAB Kuršėnų tyras. The company became one of the largest peat production companies in Lithuania.

30 April 2005

4 new Canadian pneumatic peat harvesters were purchased, the Pabalvė briquette workshop was reconstructed and expanded, and new excavators were purchased.

2007

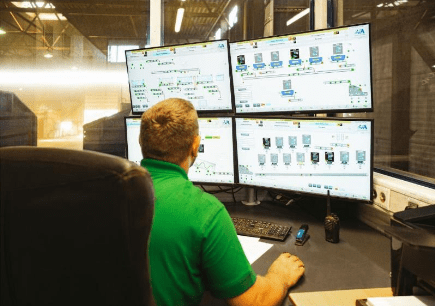

Increasing demand and quality requirements led to a major reconstruction of production facilities. A new substrate plant was built, with packaging, screening and computerised process management and quality control systems, as well as a laboratory.

2009

Biomass production for use in heating systems was begun. Investments were made in a wood chipper, a log transporter, a tracked excavator, new tractors and semi-trailers.

2010

The company participated for the first time in IPM, the horticultural fair in Essen, Germany.

2014

Operations began at the Liminėlis peatland.

2018

New packaging equipment was purchased, the processing workshop was partially rebuilt with an additional screening line, and additional storage areas for raw materials were installed.

2019

During the Covid-19 pandemic, an all-time high of 502,757 m3 of peat was processed, the heating system of the production buildings was reconstructed, the software in the processing workshop was upgraded, etc.

2020

Production of wood chip litter was begun and the peat harvesters were upgraded.

Autumn 2022

Production of wood fibre was begun.

Autumn 2023

The first bag of peat substrate for professional use was produced.

15 February 1997

4 new Canadian pneumatic peat harvesters were purchased, the Pabalvė briquette workshop was reconstructed and expanded, and new excavators were purchased.

2007

New packaging equipment was purchased, the processing workshop was partially rebuilt with an additional screening line, and additional storage areas for raw materials were installed.